close

Choose Your Site

Global

Social Media

Views: 10017 Author: Site Editor Publish Time: 2025-04-03 Origin: Site

Thanks to its comfort, efficiency, and safety, TPE (Thermoplastic elastomers) is an indispensable material in today's industries. Since TPE material combines the features of rubber and the processing advantages and recyclability of plastics, it becomes an ideal choice for many product developers, processors, and designers.

TPE is a material obtaining a wide range of physical and mechanical properties of both plastic and rubber, making it an alternative choice for many applications. Let's dig into the article for the TPE definition, its properties, and its usage with EuroPlas! Plus, there will be bonus information on EuroPlas masterbatch. Scroll down for more!

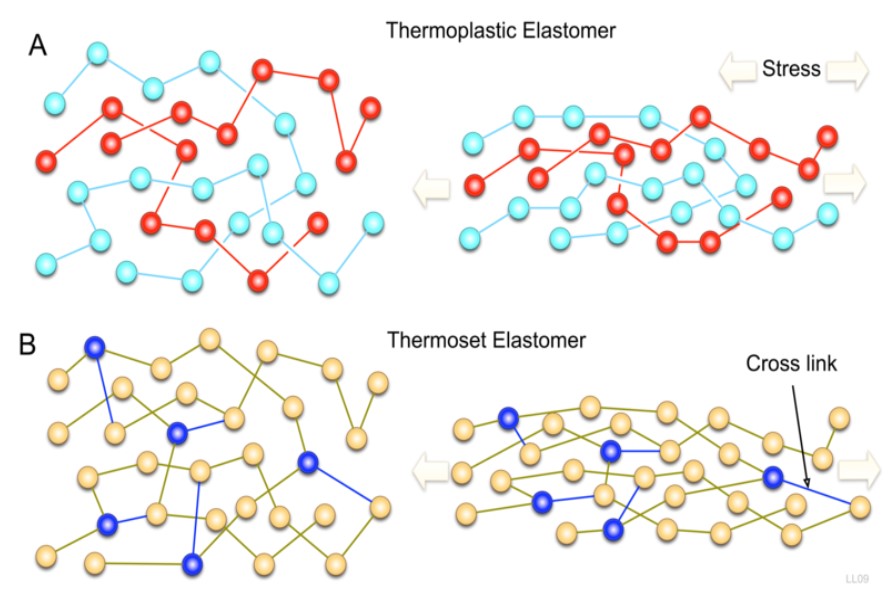

Plastic TPE is one of the most versatile plastics on the market. So, what does TPE stand for? TPE means Thermoplastic Elastomers. The abbreviation says it owns about the TPE meaning. The material is a blend of the thermoplastics' processing advantages and elastomers' excellent performance properties.

Material TPE can be quite easy to process by methods of thermoplastics, such as injection molding or extrusion, without the need for time-intensive rubber processing methods, especially vulcanization. It's possible to use TPE in advanced processing, including two-shot molding and over-molding. It also can go through secondary operations like welding and bonding to other materials.

What is TPE material? TPE plastic is also soft and flexible, like rubber. In short, it's a material with a plastic-like process but obtains the superior performance characteristics of rubber.

TPE plastic

The morphology, chemistry, and nature of the constituents determine what ultimate properties the TPE material will archive. The proportions of hard and soft phases also affect a specific property, forming a range of plastic TPE in different groups.

The hard phase has a significant influence on mechanical strength and stiffness (modulus), hardness, tear resistance, abrasion, tension, and compression below the softening point and above room temperature.

TPE has electrical insulation properties depending on the level of polarity available. In most cases, the level of electrical insulation varies from good to excellent. Thus, you can find TPE cable usually has great quality.

The thermal properties of TPE material play an important role in its performance and melting process. TPE melting point is from 260-320 degrees C, making it super suitable for high-volume injection molding and extrusion.

The material has excellent flexural fatigue resistance, high impact strength, and resistance to low temperatures (-30 degrees C).

The great thing about TPE is that compounding, reinforcing agents, stabilizers, or cure systems are almost unnecessary. Thus, batches are nearly no different. It's especially useful in improving the consistency of raw materials and fabricated products. This property makes TPE an ideal choice to replace plastic or rubber in some specific cases.

The chemistry and morphology of the plastic TPE give it excellent resistance to chemicals. It's possible to be flame retardant as well. Its chemical properties and stability are remarkable, allowing it to withstand a wide range of temperatures and other environmental factors. Since TPE is resistant to extreme variables, it's suitable for final products requiring quality and durability.

Thermoplastic Elastomer TPE

The material for the product's final use and service environment can be easily customized, thanks to the high versatility of plastic TPE. TPE tubing has different variants, ranging from soft and jelly-like to hard and ridge. Its size is also various, ranging from an inner diameter of around 0.06 inches to an outer diameter of one inch. Manufacturers also can customize the thickness of the TPE tubing's wall.

Thermoplastic elastomer TPE can go well with color and dye. It's also possible to customize it to match a full spectrum of colors and finishes, including fluorescents. You also may see medical TPE (medical tubing and other similar applications) as the material possesses good clarity properties.

Is TPE toxic? The material is made from non-toxic, recyclable plastics and is safe for the environment. Thus, if you're looking for an eco-friendly material, TPE is an excellent choice. It requires less energy during production, and factories can easily recycle it by molding or extruding it.

Compared to other materials, TPE plastic does not need complicated processing and long fabrication times. As a result, manufacturers can cut down on the final costs. The material can be an alternative option for silicone, natural rubber latex, and polyvinyl chloride (PVC) compounds.

Many people wonder about TPE material safety since it contains phthalates, a chemical added to increase flexibility and known to pose a risk to human health.

So, is TPE body safe? In general, it's safe to use thermoplastic elastomer TPE. Though it's said to have connections with hormone disruption, reproductive problems, and cancer, the levels of phthalates used in TPE products are generally low and can't harm humans. So, it's also legal to use the material. Plus, TPE causes fewer allergic reactions than latex.

TPE application

The material has had a worldwide growing market for several decades. Industries keep finding innovative ways to use TPE in more contexts. It's also ideal for plastic and rubber products, promising higher demands for the material in the future.

TPE is used in various applications in different sectors with industry-specific criteria. Here are some of its applications:

Automotive industry: control elements in automotive interiors, exterior window encapsulations, and under-the-hood seals.

Industrial products: cable grommets, tool handles, etc.

Consumer goods: packaging, toys, sports equipment, and hygiene articles (razors and toothbrushes, for example)

TPE medical applications: medical tubing, drip chambers, and seals.

In addition, another interesting thing is you can find TPE waterproof and non-waterproof, depending on how you blend it to meet the final product's requirements. In general, TPE is the gasket material to keep portable electronics safe from water. Again, it indicates the possibility of a wider range of uses for TPE plastic.